Making CNC by using Arduino

1. CNC ROUTER AND USING PURPOSE

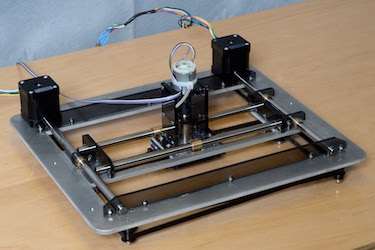

In this

project we designed and manufactured it 2 axis CNC ROUTER which name is COREXY.

2 axis CNC router, using linear motion mechanisms, stepper motor impulse taken

with that obtained from the linear motion, so that the ends of parts used for

the purpose of CNC devices are computer programs and equipment brought to the

desired position. Firstly, we did it design of it, after design completed of

its manufacturing.

2. SAMPLE CONSTRUCTİONS and DİFFERENCES

CNC router

is generally small size desktop CNC machine tools. Design of in this type of

machines usually be preferred wood for body but we preferred sheet metal, also

sheet metal is suitable for this project because it is cheap, durable etc. Most

of the like this projects usually used linear stake systems but in this project

we preferred shafts and belts instead of linear stake systems because of the

cost of its.

As a motor

for CNC ROUTER COUNTER often prefer stepper motors, ın our work we preferred 2

stepper motors and its driver A4988. Stepper motors some advantages some of

them are: they are not expensive, easy to control and high resistance to heat

loss and also they have high torque.

3. USİNG MACHİNE ELEMENTS and PARTS

3.1 MAİN FRAME: We use as a frame sheet

metal, it has some advantages some of them are: cheap, durable and hard but

also it is very heavy. The thickness of our sheet metal is 3mm.

3.2 SHAFTS, BEARİNGS,

PULLEYS and BELTS: We used 4 aluminum shafts, 3 bearings, 2 belts and 8

pulleys. A bearing is a machine element that constrains relative motion to only the

desired motion, and reduces friction between

moving parts. The design of the bearing may, for example, provide for

free linear movement of the

moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts

[] . We used 3 bearings in middle moving part and diameter of our miles is 8 mm

and also inner diameter of our linear bearings is 8 mm and we measured outer

diameter of bearing with caliper, which is near 11.6 mm.

3.3 STEP MOTORS and

MOTOR DRİVERS: Stepper motors convert the electrical energy to rotary motion.

It changes angular position in steps. Usually it can be 90, 45, 18, 7.5, 1.8

angles, we use NEMA 14 stepper motors which is 1.8 degree/200 step. For

controlling stepper motors use must motor driver or control cards.

Advantages of stepper motors

1. They easy

to gain momentum and they have constant moment of rotation. Stepper motors

usually are digital due to their production structures.

2. It

reaches maximum value of maximum dynamic torque in low speeds.

3. They are

cheap, easy to control, they don’t have brush and heat loss of stepper motors

is lower than other motors. [2]

Disadvantages of stepper motors

1. If number

of revolutions start to increase then moment of rotation decrease.

2. Finally

for stepper motors they are not appropriate high speeds application.

Stepper Motor Drivers

We use 2 A4988 stepper motor drivers, we select them because

it is cheap, easy to use and accessibility. With signals which come from

controllers, the motor drivers rotate the motors clockwise or counter clockwise.

We used this type of motor drivers easily and also normal people use this type

of drivers easily, they should be only literate.

4. MICROCONTROLLER AND SOFTWARE

We used as a microcontroller Arduino Nano because while we

searching in internet we saw them as a set, it includes 1 Arduino Nano and 3

stepper motor drivers (A4988) they are very cheap then we bought them from

China.

In above pictures are

our Arduino Nano and motor drivers shield.

Next we downloaded GRBL CONTROLLER 3.6.1 then we added GRBL

to Arduino’s library. Next, we opened GRBL from libraries then uploaded it to

Arduino. We did some arrangements in the GRBL controller program.

5. WORKING SYSTEM OF CoreXY and

MOVEMENT

The logic of working COREXY is very simple. This is a

standard drawing table. The horizontal bar is a straight-edge which can be

moved up and down (Y,-Y axes) by the user. The crisscross pattern of the cables

stabilizes the bar and keeps it horizontal.

This effect can be seen by following the direction of motion

of the two cables which comprise the mechanism. Note that all of the vertical

arrows point in the same direction.

İf we want to move horizontal bar to vertical a direction

(Y,-Y) both motors must turn opposite direction, if we want to horizontal

motion (X,-X) both motors must turn same direction.

6. WHY I PREFER COREXY?

CoreXY is made from sheet metal so it is durable, cheap,

readily available.It also simple it can be implemented with only three

structural plates, all of which can nest during fabrication. Also CoreXY

provides a fundamental building block of many computerized fabrication tools -

cartesian motion – in a simple adaptable format.

7. MAFUFACTURING AND ASSEMBLY PROCESS

1. First, Our main frame is cut by laser cutting in Ostim.

2. Second, we did assembly of our CoreXY according to looking

some photos from internet about CoreXY.

3. About our shafts, they are cut 8mm diameter and we bought

8mm inner diameter bearings from Ostim.

5. The

x and y pieces are hot glued to bearings on the aluminum rods and we linked the

belts to moving parts with toothed clips.

6. The aluminum pulleys keep the belt in tension and move

the middle moving part accordingly.

8. Conclusion

Design and production of the X-Y table will be made generally

used for hobbies.

Mechanically mounting made computer-controlled X-Y table

assembly of the stepper motors and electrical equipment and control made using

GRBL Control program is made out.

Consequently, designing and manufacturing made the computer

controlled X-Y table is operated smoothly.

Preparing by Emre Akkaya

Yorumlar

Yorum Gönder